Carbon Holdings has licensed UNIPOL® Polypropylene gas-phase process technology from W.R. Grace for its OPC facility in Egypt to manufacture polypropylene. This technology, known for its stability, predictability, and minimal equipment requirements, benefits from a simple and reliable design. When combined with SHAC® Catalyst Systems and CONSISTA® Donor Technology from Dow, it allows the plant to operate above its nameplate capacity, offering significant economic advantages. UNIPOL® Polypropylene Technology's simplicity results in lower capital and operating costs, increased reliability, and reduced maintenance expenses, making it the least complex and most efficient process for polypropylene production.

Polypropylene’s strong element is its versatility for molded, extruded, and film products. Polypropylene is tailored to most plastic applications.

OPC produces homopolymer polypropylene in four main categories: Raffia, Film, Injection, and Fiber.

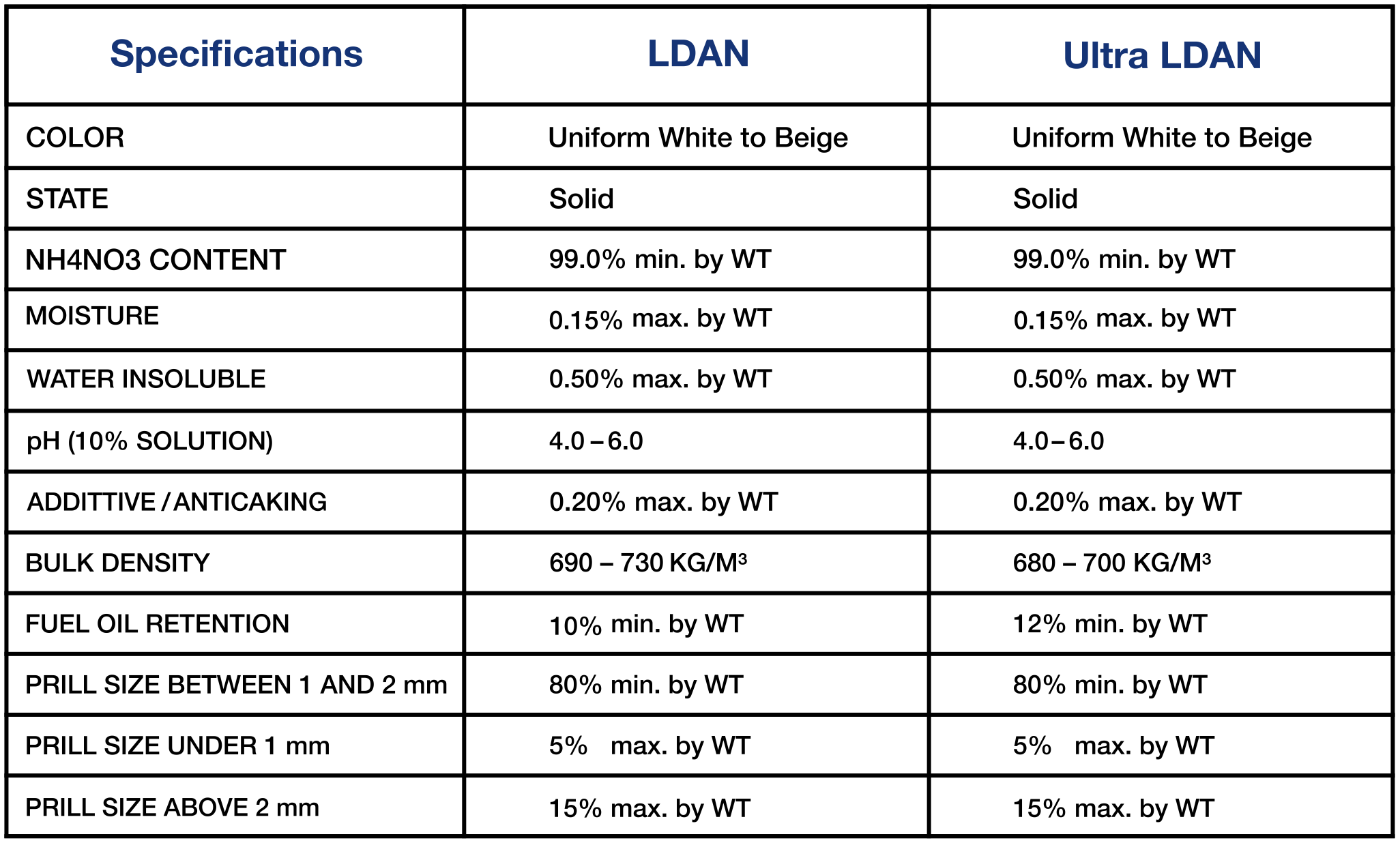

EHC’s LDAN is designed to be used as a solid oxidizer ingredient for explosive compositions for the ANFO and heavy ANFO production as the most cost-effective for dry surface and underground blasting applications.

Due to its high porosity and low density, EHC LDAN ensures high fuel oil absorption increasing the ANFO’s blasting performance.

EHC LDAN can be used for mining, quarrying, and civil construction applications.

The EHC LDAN packing conditions added to its crushing strength and low moisture retention mean EHC LDAN can stored for longer periods without any reduction in product quality.

EHC LDAN is available in 25 kg polyethylene bags, also in 1000 kg, 1100 kg or 1200 kg polypropylene jumbo bags which are protected by an inner polyethylene liner.

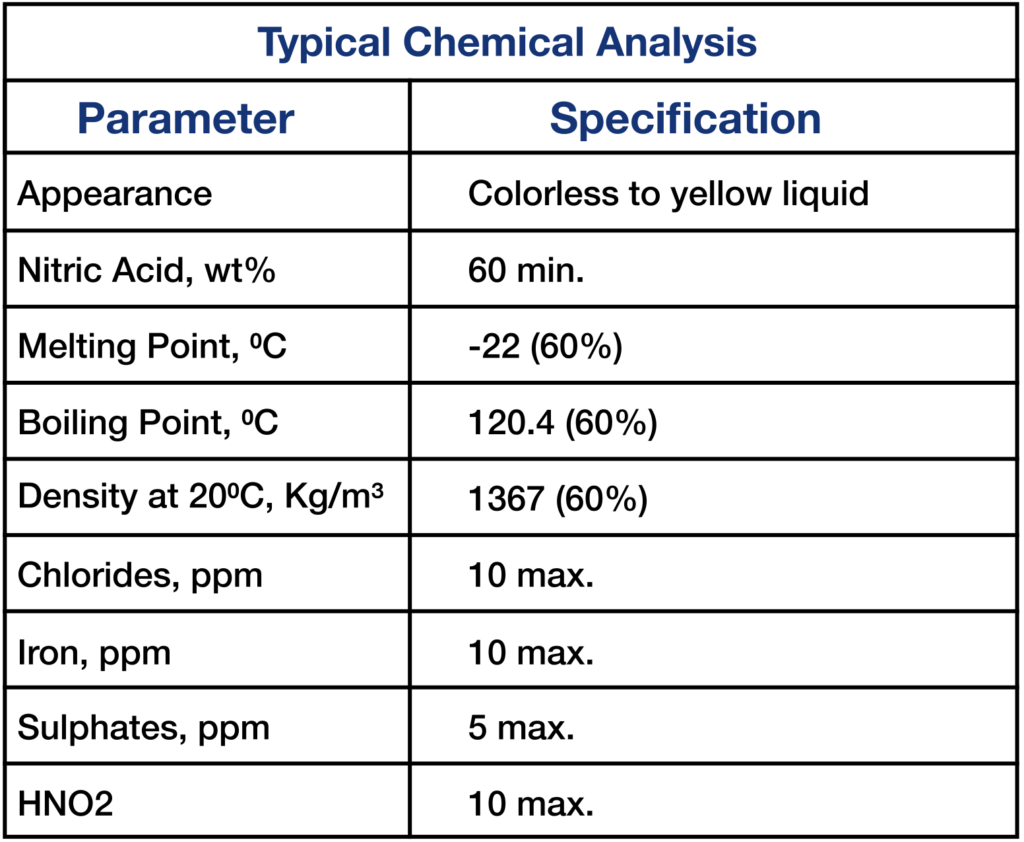

EHC Nitric Acid is a colorless liquid produced using dual pressure process by oxidizing ammonia into NOx gases over platinum knitted catalyst gauzes. The NOx gases pass through a series of coolers which is followed by the absorption process to produce 60% w/w concentration. The Nitric Acid then passes through a final bleaching stage to remove any remaining non-condensed NOx gases.

Nitric Acid is predominantly used in agriculture or the production of Ammonium Nitrate fertilizer. Other applications of Nitric Acid include:

EHC’s high purity commercial grade Nitric Acid is sold either in one-way acid-resistant composite containers or in stainless steel tanker trucks.